3D food printing facts for kids

3D food printing is the process of creating food using a 3D printer. 3D food printers use edible materials to print food just like ordinary printers use ink. The materials come out of food-grade nozzles in layers.

One major advantage of 3D food printing is that one can create unique dishes in the desired shape. Dishes can also be made to meet dietary needs and preferences.

Contents

History

Chuck Hull invented 3D printing technology in 1986 in the USA. In the 2000s, the technology was first used in food industry.

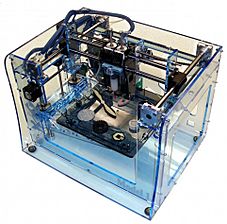

3D food printing was first tested at Cornell University and Massachusetts Institute of Technology (MIT) in 2007. The Fab@Home 3D printer was developed by a team at Cornell University in 2006. It could print foods like chocolate, cookie dough, and cheese.

General principles

Three factors are key to precise and accurate food printing:

- the materials or ingredients the printer uses

- the way and speed in which the food exits the printer

- whether the food is baked, microwaved, fried, or left the way it is after it is printed

Printing Process

First, the syringe-like container of the 3D printer is filled with the printing material. The printer then heats the material up and pushes it through a food-grade nozzle layer by layer. If dry powder ingredients are used, they are sprayed with an edible liquid to make the material solid before printing.

The printer can be programmed with pre-loaded recipes, or users can design their own food using computers, phones, or IoT devices.

Materials

The edible materials used as "ink" in the printer can be:

Additives

Sometimes additives like transglutaminase and hydrocolloids can be added to the ingredients to help the food keep its shape.

Applications

- Personal nutrition: A person with food allergies or the elderly can have food made to meet their specific needs. In October 2019, startup company Nourished 3D printed personalized nutritional gummies from 28 different vitamins. People can now take a survey and have a personalized nutritional gummy printed for them.

- Food presentation: 3D food printing allows intricate designs to be made with food. Designs are mostly made using sugar. Sometimes children will eat nutritious meals printed with a 3D printer because they like the way it looks.

- Efficient food production: Food waste happens during processing, distribution, and consumption. 3D printing can cut food waste because food that does not look nice can be used as the "ink" to make better-looking food. Upprinting Food, a Dutch startup, has been blending and combining different ingredients from food waste to create purees which are then used as materials for 3D printing. Chefs are also creating different dishes from leftover food using 3D food printers.

- Space exploration: Food that is both nutritious and easy to store in space can be printed for astronauts on long space missions.

- Medical applications: 3D food printing can be used to create food that is easier to swallow for people with dysphagia. It can also be used to create food that is easier to digest for people with gastrointestinal problems.

Challenges

- Higher printing cost: 3D food printing is currently more expensive than traditional food manufacturing. 3D printers are expensive and they require specialized food-grade materials.

- Lack of regulations: Currently, there are no specific rules for 3D food printing, which can make people nervous.

- Limited food designs: The design options for 3D food printing are limited compared to traditional ways of designing meals.

- Ingredient incompatibility: Many ingredients are not able to be used in a 3D printer.

- Food shelf life: The shelf life of 3D printed food is currently shorter than traditional food products unless it is specially packaged and stored.

- Difficulty in obtaining the right ingredients to print: It can be difficult to get the right ingredients for 3D food printing.

- Speed: The speed of 3D food printing is a major challenge. The technology is currently slower and more expensive than traditional ways of making food.

Interesting facts about 3D food printing

- Completing one 3D-printed food item can take from 7 to 45 minutes.

- Cadbury is using custom-made 3D printers for creating molds and prototypes of new sweets.

- Barilla, an Italian pasta company, is working with the Dutch research institute TNO on a pasta 3D printer able to produce little pieces of art from a durum wheat flour.

- Food 3D printing usually requires melting or mashing the ingredients to create a paste that a machine can release.

- The Chinese company Beets was able to make jelly animals and figurines from a Philadelphia cream cheese.

See also

- 3D Printing

- Multi-material 3D printing

- 3D bioprinting

- 3D Scanning

- 3D Modelling

- Fused Deposition Modeling (FDM)

- Selective Laser Sintering

- Inkjet Printing

- IoT

- Fab@Home

- Transglutaminase

- Hydrocolloids

- Viscosity

- Edible ink printing