Gunsmith facts for kids

A gunsmith is someone who makes and or designs guns. The job of a gunsmith is similar, but not the same as an armorer. The origin of the word gunsmith dates back to the 1580s.

Contents

History

The first firearms can be dated to about the 1200s in China. In Europe, the first gun barrels were made by Italian craftsmen. But gunsmithing was new in the Middle Ages. For a long time they did not have their own guilds and many joined blacksmiths’ guilds. By the mid-1400s, there were enough gunsmiths to form their own guilds. One of the first was in 1463 in Suhl, Germany. England did not develop gunsmiths as quickly as other European countries and to change this, King Henry VIII invited leading gunsmiths in Europe to come live and work in England. Many accepted and not long afterwards more gun shops began appearing in England. Several appeared in London near the Tower of London, which held the country's stockpile of guns. Soon they were training English citizens in this new trade.

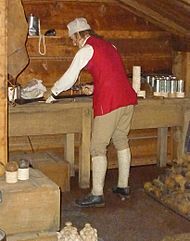

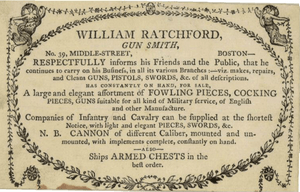

Before the American Revolutionary War in the American colonies, gunsmithing was a time-consuming process. Gunsmiths were generally gun makers who repaired their own weapons for their customers. These gunmakers came to the American colonies along with other craftsmen from England, and later from Germany and Switzerland. These were countries with long histories of gun making. Gunsmiths learned their trade by becoming an apprentice to an established gunsmith or gun maker. They worked from their adolescence into early adulthood before they could open a shop of their own. Handguns were relatively cheap and were made in large shops in England. So American gunsmiths repaired and modified imported pistols. However, muskets and rifles were not imported as much and local gunsmiths would custom make these for their customers. Their work included carving stocks, engraving metal pieces, and forging gun barrels. It could take as many as 400 hours to create guns by hand. Soon entirely new guns were created such as the Pennsylvania rifle (later called the "Kentucky rifle"). This was the product of German gunsmiths who immigrated to Pennsylvania in the early 18th century. It was lighter, longer and more accurate than European designs. The rifle soon became the favorite of colonial settlers and Frontiersmen.

About the middle of the 18th century, gunsmith Honoré Blanc developed the concept of interchangeable parts for muskets. Blanc tried to interest other European gunsmiths, but they were not impressed by the idea. But he did interest the American Ambassador to France, Thomas Jefferson. Jefferson quickly saw that mass production of weapons parts would free America from dependence on European sources for parts. He couldn't get Blanc to move to the United States but he did convince President George Washington it was a good idea. In 1798, Eli Whitney got the first contract for 12,000 muskets built under the new system. Whitney used a large force of unskilled workers and machinery to produce standardized identical parts at a low cost. This was about the time Gun manufacturers began to be distinguished from gunsmiths.

Overview

Gunsmiths may be employed in:

- factories by firearms manufacturers in their in-house Custom Shop,

- armories by military or law-enforcement agencies,

- sporting goods stores, or

- small gunsmith shops, as either the owner, or as one of a handful of employees.

To pursue the entirety of this trade, a gunsmith must possess skills as a parts fabricator, a metalworker or blacksmith, a woodworker and an artisan; be knowledgeable in shop mathematics, ballistics, chemistry, and materials engineering; be knowledgeable in the use and application of a variety of hand, power, and machinists tools and measuring devices. Those who are (self-) employed in small gunsmith shops must also possess skills as small business operators; work effectively with a wide variety of customers; and remain abreast of, and comply with federal, state, and local laws, ordinances, and requirements.

Due to the great breadth of subject matter to be mastered, many gunsmiths specialize in only a few of the skills required of the general gunsmith. Alternatively, some gunsmiths learn many of the skills of the trade but only apply them to a few weapon types (e.g., only pistols, only shotguns, only specific brands or models).

Responsibilities

The primary responsibility of a gunsmith is to ensure that guns work and function safely. Gunsmiths accomplish this by always properly observing and demonstrating gun safety in their handling procedures, both in their own actions and the actions of their customers and the people around them.

They accomplish that task secondly by inspecting guns to ensure safe mechanical operation. Gunsmiths use their in-depth knowledge of firearms and manufacture gun schematics to guide inspections: repairing deficiencies, notifying customers of unsafe conditions, or preventing catastrophic failures.

Some of the conditions a gunsmith looks for when inspecting a firearm brought to them for repairs are improper assembly, missing parts, cracks, bore obstruction, improper headspace, improper timing, safety malfunctions, worn sear edges, and deformed firing pin tips, among other problems.

*Gun schematics, also referred to as firearm schematics, are technical diagrams that display a firearm's internal workings and parts. These schematics usually feature detailed illustrations of significant components like the barrel, receiver, trigger assembly, and magazine. They are often used by gun enthusiasts, manufacturers, and gunsmiths to diagnose and fix problems that may arise with the firearm.

Common tasks

(listed in approximate, but not exact, order of increasing difficulty)

- Disassemble, clean, inspect, lubricate and reassemble.

- Remove corrosion and touch-up finish.

- Repair burred or damaged parts with files and stones.

- Replace defective parts with factory-made replacements, hand-fitting as necessary.

- Add after-market customizations:

- sling-swivels

- recoil-pads

- iron-sights

- scopes

- grip caps

- butt plates

- Repair and re-finish wooden stock parts.

- Checker or re-checker grip areas.

- Deepen or clean up worn or damaged engravings and markings.

- Re-crown damaged muzzles on a lathe.

- Repair dented shotgun barrels.

- Install (solder) or repair rib on shotgun barrels, or repair double-barrel assemblies.

- Measure and correct head-space dimensions.

- Check for excessive bore erosion.

- Troubleshoot and repair feeding, ejecting and firing problems.

- Test-fire guns with conventional loads to ensure proper operation.

- Fabricate wooden stocks to customer specifications and body dimensions. Fit same to existing receiver and barrel.

- Glass-bed actions to stocks to improve accuracy.

- Remove existing metal finish, and re-blue metal parts.

- Fabricate replacement parts from metal stock.

- Modify trigger-pull weight through careful stoning of trigger mechanism parts.

- Fire proof-loads through weapons to ensure sufficient strength of parts under over-load conditions.

- Replace worn barrels, which have fired so many rounds that they are no longer of the specified caliber (which leads to loss of accuracy).

- Change caliber or cartridge of existing rifle, by changing barrel, and modifying receiver.

- Re-cut rifling and change caliber of existing barrel.

- Design and build complete rifles by fitting stock barrels to stock receivers; fabricating or purchasing additional parts as needed, and fitting same to rifle. Fitting custom stock to the same.

- Design and build a complete rifle, shotgun, or combination gun from start to finish. (Combination guns, usually referred to as a "Drilling", is a highly complex hand-made long gun with several joined barrels combining both rifle and shotgun calibers and gauges sharing a common breech and buttstock.) The highest level examples of custom-made firearms usually start out as several pieces of blank steel stock or rough forged parts, a slab (stock blank) of walnut; steel tubes with rifled or smooth holes ("bores") drilled their length, and are usually hand made by highly skilled gunsmiths using nothing more than an occasional lathe, milling machine, heat treating furnace (for making springs, hardening parts to the proper hardness, and color case hardening) with the majority of roughing, fitting, and finishing done completely by hand using files, scrapers, abrasive paper and cloth, chisels and rasps.

Specializations

While some gunsmiths are general practitioners in this trade, some of the more important specializations are:

Custom builder/designer

Builds guns to customer's specification, from raw materials and shelf parts. Gunsmiths specializing in custom areas can be called upon by professional target-shooters, avid sports shooters, or anyone that wants custom attributes added to their firearm to create highly accurate or custom looking firearms. A Custom Gunsmith also builds high-end firearms for hunters and shooters with needs and desires that cannot be served by standard catalogued firearms offered by gun manufacturers. They may work in partnership with engravers and other specialized artists to produce unique finishes and decorations not possible on regular mass-produced firearms. Some highly specialized gunsmiths can complete all firearm modifications without anyone else in the industry helping them. This is likely the most highly skilled of gunsmiths, as they are required not only to have proficiency in the other areas of gunsmithing, but must also be well educated in firearm finishing and machining, in order to manufacture the individual components and even springs before assembly takes place.

Finisher

Applies various chemical processes (browning, bluing, Parkerization, among others) to the metal parts of guns to develop corrosion resistant surface layers on the steel. They may also apply case hardening to low carbon steel parts. Case hardening is a combined chemical and heat-treatment process which introduces carbon into the surfaces of low steel alloys that does not contain sufficient carbon to allow total ("through") heat treatment. This carbon rich surface is then heat treated resulting in a thin, very hard surface layer with a tough, malleable core. This process can be done solely for the mechanical properties (hardness and toughness) it imparts, or, by packing the parts in bone charcoal and other chemicals and heating in a heat treatment furnace for varying time periods, it is possible to introduce rich colors into the carbonized surface. This type of case hardening, known as color case hardening, is prized for its rich mottled blues, purples, browns and grey tones. It is possible, with highly skilled craftsmen using highly proprietary processes, to control the hues and patterns so closely that one familiar with high grade custom firearms can usually recognize the maker of another shooter's firearm solely by the colors and patterns on its parts; an important distinction on extremely costly firearms of the highest grade. Typically, its use is usually restricted to receivers, rarely barrels. Although providing corrosion resistance, the colored surface layers are subject to wear and may also fade with time. Antique firearms for sale frequently note the specific percentage of the factory original case coloring remaining on the receiver and lockplates. Renewing this color case hardening to the specific patterns of the firearm when it was new has become an important sub-area of the gunsmithing field.

Stockmaker

Carves gun stocks from wood (usually walnut; although birch, maple, and apple wood, among others, are frequently seen). Fits stocks to the metal parts of the gun (receiver and barrel), as well as to customer's body dimensions. With custom made shotguns, the fit to the individual shooter is vital, as the shot cloud's impact is largely determined by the way the stock fits the shooter. Very high grade firearms may have stocks fashioned from very costly blanks, mostly of one of the walnut varieties, specially chosen for its rare and highly figured grain. The fashioning of high end gunstocks calls for an extremely high level of skill and craftsmanship, as the finished product must be pleasing aesthetically, fit the shooting customer like an orthopedic device, all the while having the ability to withstand high levels of recoil from the firing of many thousands of rounds. Wood gunstocks may be fashioned with automated machinery (for production firearms) while high end gunstocks are hand made using saws, chisels, gouges, rasps, and files. The surfaces are then finished by sanding, scraping, staining, oiling, or lacquering.

Checkerer

(This specialization is frequently combined with that of the Stockmaker) Uses checkering tools to create an ornate pattern of small raised diamonds in the wood surfaces which are to be gripped. The checkering tools are in effect tiny saws, designed to leave a v-shaped groove (of approximately 60 to 90 degrees) in the surface of the wooden gunstock. Special checkering tools consisting of two saw blades in parallel are used to set the spacing, usually between 16 and 24 lines per inch (1.0 mm to 1.6 mm line width). The area to be checkered is covered by one set of such grooves parallel to each other. A second set of parallel grooves is then executed across the first set, at approximately a 30-degree angle, leaving the area covered with small, pointed diamonds. The edges of the checkered area are frequently ornamented with simple bas-relief wood carving, frequently variations on the fleur-de-lis.

Gun engraver

Uses hand-gravers or die-sinker's chisels to cut designs or pictures into the metal surfaces of the gun, primarily the receiver. The firearms engraver must first be a highly gifted and capable artist that can first compose the desired design freehand on paper. In many cases, the customer must be consulted and must approve the design. In some cases, the engraving may incorporate a favorite scene, a revered hunting dog, or even family members and residences. The engraver must have a thorough knowledge of human and animal anatomy, perspective, botany, and composition. The smallness and geometry of the parts must also be considered, and harmony between all these factors must artistically agree.

These designs must then be cut freehand into the tough hardened steel surfaces of the firearm. Pneumatically driven engraving systems, such as the Gravermeister, developed by GRS Tools, may be used to replace or supplement hand-powered engraving, but the guiding of these powered tools is still provided by the artist. Other metals (especially gold and silver) may be inlaid and engraved to further the design. Designs usually consist of elaborate scroll-work based upon Acanthus leaves or vines, or may be of purely abstract spirals. Before the development of corrosion resistant surface treatments for steel, gun surfaces were engraved to retain more oil to prevent rust. In modern usage, guns are engraved purely for artistic reasons. Top grade engraving is very expensive but well executed, tastefully designed engraving always adds significantly to the value of quality firearms. Many of the world's foremost art museums have highly decorated firearms in their collections because of the high artistic merit and craftsmanship of their engraved, chiseled, and carved decoration. Many books exist on the subject of highly decorated firearms, with detailed illustrations showing their "art in steel".

Pistolsmith

Specializes in work on pistols and revolvers. Pistolsmiths should be proficient in a range of skills such as woodworking, checkering, machining, metal finishing and metalworking. They must have an excellent understanding of the mechanical characteristics and function of the guns they work on. Often a pistolsmith is called on for extensive customization of a handgun making it better suited for its intended purpose. A good example of this is changing the factory sights for new front and rear sights more suited to the purposes of the user. A wide variety is available as aftermarket parts. Target pistols usually start out as standard models but receive extensive reworking by skilled pistolsmiths resulting in a firearm that is capable of much greater accuracy than the standard versions of the same arm. A more advanced job a pistolsmith may called on to perform is to construct a completely hand fitted target arm using a serial numbered frame as the base (as required by law) with the rest of the parts supplied with excess metal in certain areas by specialist manufacturers so the pistolsmith can fit these parts together to exacting tolerances. Using these methods, the pistolsmith can build highly accurate firearms that greatly exceed the usual accuracy of standard models of the same model.

Manufacturer

Some gunsmiths used their experience and skills to become small-operation manufacturers, specializing in making only a few types of gun parts, for sale to other gunsmiths and gunmakers. Some of the more important part categories are barrels, trigger assemblies, receivers, and locks.

Notable gunsmiths

- Honoré Blanc (1736-1801), French gunsmith who pioneered the use of interchangeable parts

- Hugo Borchardt (June 6, 1844 – May 8, 1924), German firearms inventor and engineer, invented the Borchardt C-93 pistol and Sharps-Borchardt Model 1878 rifle.

- Nicolas-Noël Boutet (August 31, 1761 – 1833), French gunsmith, bladesmith, director of Versailles state arms factory

- Browning family

- Jonathan Browning (October 22, 1805 – June 21, 1879), American pioneer and firearms inventor. Was a notable producer of harmonica guns, an early type of repeating rifle.

- John M. Browning (January 23, 1855 – November 26, 1926), firearms inventor and designer. Created many notable firearms, including the Browning Auto-5, Winchester Model 12, the Browning Automatic Rifle, M1911 pistol, and the M1919 Browning and M2 Browning.

- Val A. Browning (August 20, 1895 – May 16, 1994), weapons designer and engineer. Designed the Browning Double Automatic Shotgun.

- Henry Deringer (October 26, 1786 – February 28, 1868), inventor of the Derringer pistol.

- Louis-Nicolas Flobert (1819 - 1894), French inventor of the first rimfire metallic cartridge in 1845.

- John Garand (January 1, 1888 – February 16, 1974), Canadian-American firearms designer, inventor of the M1 Garand.

- Richard Jordan Gatling (September 12, 1818 – February 26, 1903), inventor of the Gatling gun.

- Jacob and Samuel Hawken (1786 – 1849, 1792 – 1884), American gunsmiths, designed the Hawken rifle.

- Alexander Henry (1818-1894), Scottish gunsmith, designed the Henry rifling and barrel used in the Martini–Henry rifle.

- Benjamin Tyler Henry (March 22, 1821–December 29, 1898), American gunsmith, inventor of the Henry rifle.

- Kunitomo Ikkansai (November 21, 1778 – December 26, 1840), Japanese gun manufacturer.

- Erik Jørgensen (17 May 1848 – 1896), Norwegian gunsmith, noted for his part in developing the Krag–Jørgensen rifle.

- Mikhail Kalashnikov (10 November 1919 – 23 December 2013), Soviet firearms designer, inventor of the AK-47 and AK-74 line of assault rifles.

- Ole Herman Johannes Krag (7 April 1837 – 9 December 1916), Norwegian military officer and weapons designer, noted for his part in developing the Krag–Jørgensen rifle.

- Jean Alexandre LeMat (1824–1883), French gunsmith, inventor of the LeMat revolver.

- Georg Luger (March 6, 1849 – December 22, 1923), Austrian weapons designer, inventor of the Luger pistol and the 9×19mm Parabellum cartridge.

- Nikolay Makarov, (May 22, 1914 – May 13, 1988), Soviet weapons designer, inventor of the Makarov pistol.

- Mauser family

- Paul Mauser (June 27, 1838 – May 29, 1914), German weapons designer, manufacturer, and industrialist.

- Wilhelm Mauser (May 2, 1834 – January 13, 1882), German weapons designer, manufacturer, and industrialist.

- Hiram Maxim (February 5, 1840 – November 24, 1916), American-born inventor and later naturalized British subject, known as the inventor of the Maxim gun.

- Bob Munden (February 8, 1942 – December 10, 2012), gunsmith and exhibition shooter.

- Evelyn Owen (1915 - 1949), Australian gunsmith and inventor of the Owen submachine gun.

- William B. Ruger (June 21, 1916 – July 6, 2002), American gunsmith and co-founder of Sturm, Ruger & Company.

- Dieudonné Saive (1889–1973), Belgian small arms designer, inventor of the FN Model 1949 and the FN FAL.

- Giulio V. Savioli (June 12, 1933 – July 31, 2009), Italian-American firearms designer and gunsmith.

- Eugene Stoner (November 22, 1922 – April 24, 1997), American firearms designer, inventor of the ArmaLite AR-15, later adopted for military use as the M16 rifle.

- Patrick Sweeney, American gunsmith, author, and editor of Guns & Ammo magazine.

- John T. Thompson (December 31, 1860 – June 21, 1940), United States Army officer, inventor of the Thompson submachine gun.

- Fedor Tokarev (2 June 1871 – 6 March 1968), Russian weapons designer, designed the Tokarev pistols and rifles.

- Ernest Vervier, Belgian gunsmith, designed the FN MAG and FN Minimi.

- Carl Walther (November 22, 1858 – July 9, 1915), German gunsmith, founder of the firm Carl Walther GmbH Sportwaffen.

Images for kids

See also

In Spanish: Armero (profesión) para niños

In Spanish: Armero (profesión) para niños