SpaceX Starship development facts for kids

SpaceX Starship is the second stage of the Starship system. Its development took place under a changing set of names and programs beginning in 2005, when American aerospace company SpaceX first publicly mentioned a second stage rocket concept. The rocket evolved through many design changes. On 25 July 2019, Starhopper performed the first successful flight at SpaceX Starbase near Boca Chica, Texas. SN15 was the first test article to take off and land successfully, in May 2021.

History

In November 2005, SpaceX first referenced a launch vehicle concept with Starship's capabilities. Musk briefly mentioned a theoretical heavy‑lift launch vehicle code-named BFR, powered by a larger version of the Merlin engine called Merlin 2.

As early as 2007, Musk stated a personal goal of eventually enabling human exploration and settlement of Mars. SpaceX began development of the Raptor rocket engine before 2014. From 2011 to 2014, Musk made various statements expressing his hope that SpaceX would send humans to Mars in the 2020s or 2030s.

Mars Colonial Transporter

In October 2012, Musk first publicly articulated a high-level plan to build a reusable rocket system with substantially greater capabilities than the Falcon 9. The launch vehicle was described as part of the company's Mars system architecture, then known as Mars Colonial Transporter (MCT). The idea included reusable rocket engines, launch vehicles and space capsules to transport humans to Mars and return them to Earth. SpaceX CEO Gwynne Shotwell mentioned that the payload could reach 150–200 tons to low Earth orbit. The MCT vehicle was to be "an evolution of SpaceX's Falcon 9 booster ... much bigger [than Falcon 9]."

In June 2013, Musk stated that he intended to defer SpaceX's IPO until after the "Mars Colonial Transporter is flying regularly."

In February 2014, the principal payload for the MCT was announced to be a large interplanetary spacecraft, capable of carrying up to 100 tonnes (220,000 lb) of passengers and cargo. According to SpaceX engine development head Tom Mueller, SpaceX could use nine Raptor engines on a single rocket, just as the Falcon 9 booster used nine Merlin engines. The rocket would be at least 10 meters (33 ft) in diameter — nearly three times the diameter and over seven times the cross-sectional area of the Falcon 9 booster cores. It was expected to have up to three cores totaling at least 27 engines.

Interplanetary Transport System

Artist's conception of the ITS at liftoff

|

|

| Function |

|

|---|---|

| Manufacturer | SpaceX |

| Country of origin | United States |

| Size | |

| Height | 122 m (400 ft) |

| Diameter | 12 m (39 ft) |

| Mass | 10,500 t (23,100,000 lb) |

| Stages | 2 |

| Capacity | |

| Payload to LEO | 300 t (660,000 lb) (reusable) 550 t (1,210,000 lb) (expendable) |

| Payload to Mars | 450 t (990,000 lb) (with refueling) |

| Associated rockets | |

| Derivatives | Big Falcon Rocket |

| Launch history | |

| Status | Developed into the BFR |

| Launch sites | KSC LC-39A |

| First stage – ITS Booster | |

| Length | 77.5 m (254 ft) |

| Diameter | 12 m (39 ft) |

| Empty mass | 275 t (606,000 lb) |

| Gross mass | 6,975 t (15,377,000 lb) |

| Propellant mass | 6,700 t (14,800,000 lb) |

| Engines | 42 Raptor |

| Thrust | 128 MN (29,000,000 lbf) |

| Specific impulse | 334 s (3.28 km/s) |

| Fuel | Subcooled LCH4 / LOX |

| Second stage – ITS Tanker | |

| Length | 49.5 m (162 ft) |

| Diameter | 12 m (39 ft) 17 m (56 ft) (incl. legs) |

| Empty mass | 90 t (200,000 lb) |

| Gross mass | 2,590 t (5,710,000 lb) |

| Propellant mass | 2,500 t (5,500,000 lb) |

| Engines | 3 Raptor 6 Raptor Vacuum |

| Thrust | 31 MN (7,000,000 lbf) |

| Fuel | Subcooled LCH4 / LOX |

| Second stage – Interplanetary Spaceship | |

| Length | 49.5 m (162 ft) |

| Diameter | 12 m (39 ft) 17 m (56 ft) (incl. legs) |

| Empty mass | 150 t (330,000 lb) |

| Gross mass | 2,100 t (4,600,000 lb) |

| Propellant mass | 1,950 t (4,300,000 lb) |

| Engines | 3 Raptor 6 Raptor Vacuum |

| Thrust | 31 MN (7,000,000 lbf) |

| Fuel | Subcooled LCH4 / LOX |

In 2016, Musk abandoned the Mars Colonial Transporter name, as the system would be able to "go well beyond Mars", in favor of Interplanetary Transport System (ITS). That year he unveiled details of the space mission architecture, launch vehicle, spacecraft, and Raptor engines. The first firing of a Raptor engine occurred on a test stand in September 2016.

In October 2016, Musk indicated that the initial prepreg carbon-fiber tank test article, built with no sealing liner, had performed well in cryogenic fluid testing. A pressure test at approximately 2/3 of the design burst pressure was completed in November 2016.

In July 2017, Musk indicated that the architecture had evolved since 2016 in order to support commercial transport via Earth-orbit and cislunar launches.

Design

The ITS stack was composed of two stages. The first stage was to be a launch booster, while the second stages would be either an "Interplanetary Spaceship" for crewed transport or an "ITS tanker" for orbital refueling. Both stages were to be powered by Raptors.

The Raptor was a bipropellant liquid rocket engine in a full flow staged combustion cycle, with liquid methane fuel and liquid oxygen oxidizer. Both propellants would enter the combustion chamber in the gas phase. A bleed-off of the high-pressure gas would provide autogenous pressurization of the propellant tanks, eliminating the Falcon 9's problematic high-pressure helium pressurization system.

The overall launch vehicle height, (first and second stages), was 122 m (400 ft). Both stages were to have been constructed of lightweight carbon fiber, including the deep-cryogenic propellant tanks, a major change from the Falcon 9's aluminum-lithium alloy tank and structure material. Both stages were to be fully reusable and land vertically. Gross liftoff mass was to be 10,500 t (1,650,000 st) at a lift-off thrust of 128 meganewtons (29,000,000 lbf). ITS was to carry a payload to low Earth orbit of 550 tonnes (1,210,000 lb) in expendable-mode and 300 tonnes (660,000 lb) in reusable mode.

ITS booster

The ITS booster was a 12 m-diameter (39 ft), 77.5 m-high (254 ft), reusable first stage, to be powered by 42 sea-level rated engines each producing some 3,024 kilonewtons (680,000 lbf) of thrust. Total booster thrust would have been approximately 128 MN (29,000,000 lbf) at liftoff, several times the 36 MN (8,000,000 lbf) thrust of the Saturn V.

The engine configuration included 21 engines in an outer ring and 14 in an inner ring. The center cluster of seven engines was to be gimbaled for directional control, although some directional control was to be performed via differential thrust on the fixed engines. Thrust on each engine was aimed to vary between 20 and 100 percent of rated thrust.

The propellants would also power the reaction control thrusters, while in the gas phase. These thrusters would control booster orientation in space, as well as improve accuracy during landing.

The design goal was to achieve a separation velocity of approximately 8,650 km/h (5,370 mph) while retaining about 7% of the initial propellant to achieve a vertical landing at the launch pad.

The design called for grid fins to guide the booster during atmospheric reentry. The booster return flights were expected to encounter loads lower than the Falcon 9, principally because the ITS would have both a lower mass ratio and a lower density. The booster was to be designed for 20 g nominal loads, and possibly as high as 30–40 g.

In contrast to the landing approach used on SpaceX's mid-2010s reusable rocket first stages—either a large, flat concrete pad or downrange floating landing platform, the ITS booster was to designed to land on the launch mount itself, for immediate refueling and relaunch.

Second stage

The ITS did not have a dedicated single-function second stage for achieving orbit. Instead, the second stage function of reaching orbit was a secondary role for a spacecraft capable of long-duration spaceflight.

The Interplanetary Spaceship was a large passenger-carrying spacecraft design proposed in September 2016. The ship would operate as a second-stage, and as an interplanetary transport vehicle for cargo and passengers. The Interplanetary Spaceship would be able to transport up to 450 tonnes (990,000 lb) per trip to Mars following refueling in Earth orbit. The three sea-level Raptor engines would be used for maneuvering, descent, and landing, as well as an initial ascent from the Mars surface.

The ITS tanker was second stage propellant tanker variant. This design was to be used to transport up to 380 tonnes (840,000 lb) of propellants to low Earth orbit to refuel Interplanetary Spaceships. After refueling operations, the reusable tanker was to reenter the Earth's atmosphere, land, and be prepared for another tanker flight.

Reusability

Both stages were to be designed to be fully reusable and were to land vertically, using Falcon 9-generation technologies.

Importantly, the "fully and rapidly reusable" aspect of the ITS design was the largest factor in the SpaceX analysis for reducing the cost of transporting mass to space. While the 2016-17 system under development relied on several cost-reducing elements, reusability alone was claimed to reduce that cost by approximately 2 1/2 orders of magnitude over NASA's previous missions. Musk stated that this was over half of the 4 1/2 orders of magnitude that he claimed was needed to enable a sustainable beyond-Earth settlement.

Big Falcon Rocket

2017 artist's conception of the Big Falcon Ship (BFS) with payload bay door open

|

|

| Function |

|

|---|---|

| Manufacturer | SpaceX |

| Country of origin | United States |

| Size | |

| Height | 106 m (348 ft) |

| Diameter | 9 m (30 ft) |

| Stages | 2 |

| Capacity | |

| Payload to LEO | 150 t (330,000 lb) (reusable) |

| Associated rockets | |

| Derivatives | SpaceX Starship system |

| Launch history | |

| Status | Developed into the Starship system |

| Launch sites | KSC LC-39A |

| First stage – Big Falcon Booster | |

| Diameter | 9 m (30 ft) |

| Engines | 31 Raptor |

| Thrust | 62 MN (14,000,000 lbf) |

| Fuel | Subcooled LCH4 / LOX |

| Second stage – Big Falcon Ship | |

| Diameter | 9 m (30 ft) |

| Engines | 2 (later 3) sea-level Raptor 4 vacuum Raptor |

| Fuel | Subcooled LCH4 / LOX |

In September 2017, at the 68th annual meeting of the International Astronautical Congress, Musk announced a new launch vehicle called the Big Falcon Rocket (BFR). He said, "we are searching for the right name, but the code name, at least, is BFR." Its goal was to send two cargo missions to Mars in 2022, with the goal to "confirm water resources and identify hazards" while deploying "power, mining, and life support infrastructure" for future flights. This would be followed by four ships in 2024, two crewed BFR spaceships plus two cargo-only ships carrying equipment and supplies for a propellant plant.

The design balanced objectives such as payload mass, landing capabilities, and reliability. The initial design showed the ship with six Raptor engines (two sea-level, four vacuum) down from nine in the previous ITS design. The engine layout, reentry aerodynamic surface designs, and even the basic material of construction each changed thereafter.

By September 2017, Raptors had been test-fired for a combined total of 20 minutes across 42 test cycles. The longest test was 100 seconds, which was limited by the size of the propellant tanks. The test engine operated at 20 MPa (200 bar; 2,900 psi). The flight engine aimed for 25 MPa (250 bar; 3,600 psi), on the way to 30 MPa (300 bar; 4,400 psi) in later iterations. In November 2017, Shotwell indicated that approximately half of all development work on BFR was focused on the engine.

SpaceX looked for manufacturing sites in California, Texas, Louisiana, and Florida. By September 2017, SpaceX had already started building launch vehicle components: "The tooling for the main tanks has been ordered, the facility is being built, we will start construction of the first ship [in the second quarter of 2018.]"

By early 2018, the first carbon composite prototype ship was under construction, and SpaceX had begun building a new production facility at the Port of Los Angeles.

In March, SpaceX announced that it would manufacture its launch vehicle and spaceship at a new facility on Seaside Drive at the Port of Los Angeles. By May, approximately 40 SpaceX employees were working on the BFR. SpaceX planned to transport the launch vehicle by barge, through the Panama Canal, to Cape Canaveral for launch.

In August 2018, the US military publicly expressed interest in using the BFR. The head of USAF Air Mobility Command was specifically interested in its ability to move up to 150 t (330,000 lb) of cargo anywhere in the world in under 30 minutes, for "less than the cost of a C-5".

Design

The BFR was106-meter (348 ft) tall, 9-meter (30 ft) in diameter, and made of carbon-fiber.

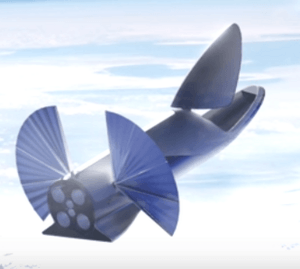

The upper stage, known as Big Falcon Ship (BFS), included a small delta wing at the rear end with split flaps for pitch and roll control. The delta wing and split flaps were said to expand the flight envelope to allow the ship to land in a variety of atmospheric densities (vacuum, thin, or heavy atmosphere) with a wide range of payloads. The BFS originally had six Raptor engines, with four vacuum and two sea-level. By late 2017, SpaceX added a third sea-level engine (totaling 7) to increase engine-out capability and allow greater payload landings.

Three BFS versions were described: BFS cargo, BFS tanker, and BFS crew. The cargo version would be used to reach Earth orbit as well as carry cargo to the Moon or Mars. After refueling in an elliptical Earth orbit, BFS could land on the Moon and return to Earth without further another refueling.

Additionally, the BFR could theoretically carry passengers/cargo in Earth-to-Earth transport, delivering its payload anywhere within 90 minutes.

Starship and Super Heavy

In 2018 Musk announced a planned 2023 lunar circumnavigation mission (#dearMoon project). He showed a redesigned BFS concept with three rear fins and two front canard fins, replacing the previous delta wing and split flaps. The revised design used seven Raptor engines. The design had two small actuating canard fins near the nose, and three large fins at the base, two of which would actuate, with all three serving as landing legs.

The two major parts were renamed to Starship (second stage) and Super Heavy (booster stage). In 2019, SpaceX began to refer to the Starship/Super Heavy combination as the SpaceX Starship system,

Stainless steel

In January 2019, Musk announced a major design change: Starship and Super Heavy would be made from stainless steel instead of carbon fiber. His stated reason was that "stainless steel was "obviously cheap, it's obviously fast—but it's not obviously the lightest. But it is actually the lightest. If you look at the properties of a high-quality stainless steel, the thing that isn't obvious is that at cryogenic temperatures, the strength is boosted by 50 percent." The high melting point of 300-series steel would eliminate the need for a heat shield on Starship's space-facing side, while the much hotter Earth-facing side would be cooled by allowing fuel or water to bleed through micropores in a double-wall stainless steel skin, removing heat by evaporation.

Both rockets were assemblies of vertically stacked steel cylinders (rings) welded to each other.

In 2019, the design reverted to six Raptor engines, with three optimized for sea-level and three optimized for vacuum. Initial Super Heavy test flights would use fewer engines, perhaps approximately 20.

Later in 2019 Musk stated that Starship was expected to have empty mass of 120 t (120,000 kg; 260,000 lb) and be able to initially transport a payload of 100 t (100,000 kg; 220,000 lb) growing to 150 t (150,000 kg; 330,000 lb) over time. Musk hinted at an expendable variant that could place 250,000 kg into low orbit.

The Raptor design was refined; higher thrust versions tested well. The initial 37 engines were reduced to 31 in 2020. Musk stated that SpaceX would complete hundreds of cargo flights before carrying human passengers.

In February 2021 SpaceX completed raising US$3.5 billion in additional equity financing. In April, SpaceX publicly forecast that Earth-Earth passenger flights would be common within five years.

Atmospheric descent tests in 2020-2021 emboldened SpaceX to make Starship's body flaps narrower and lighter.

Second stage prototypes

SpaceX prototypes are subjected to many tests before one is launched. Proof pressure tests come first. The tanks are filled with a liquid or gas to test their strength and safety factor. SpaceX may test some tanks beyond the specified limit, to find the point at which they burst. The engines were tested in later prototypes, while the vehicle remained tethered to the ground (static fire). After passing these tests vehicles either fly within the atmosphere, or launch to orbit.

| Name | First spotted | First static fire | Maiden flight | Decommissioned | Construction site | Status | Flights |

|---|---|---|---|---|---|---|---|

| Starhopper | December 2018 | 3 April 2019 | 25 July 2019 | August 2019 | Boca Chica, Texas | Repurposed | 2 |

| Mk1 | December 2018 | N/A | N/A | 20 November 2019 | Boca Chica, Texas | Destroyed | 0 |

| Mk2 | May 2019 | N/A | N/A | November 2019 | Cocoa, Florida | Scrapped | 0 |

| Mk3/SN1 | c. October 2019 | N/A | N/A | 28 February 2020 | Boca Chica, Texas | Destroyed | 0 |

| Mk4 | c. September 2019 | N/A | N/A | November 2019 | Cocoa, Florida | Scrapped | 0 |

| SN3 | March 2020 | N/A | N/A | 3 April 2020 | Boca Chica, Texas | Destroyed | 0 |

| SN4 | April 2020 | 5 May 2020 | N/A | 29 May 2020 | Boca Chica, Texas | Destroyed | 0 |

| SN5 | April 2020 | 27 July 2020 | 4 August 2020 | February 2021 | Boca Chica, Texas | Scrapped | 1 |

| SN6 | May 2020 | 23 August 2020 | 3 September 2020 | January 2021 | Boca Chica, Texas | Scrapped | 1 |

| SN8 | July 2020 | 20 October 2020 | 9 December 2020 | 9 December 2020 | Boca Chica, Texas | Destroyed | 1 |

| SN9 | August 2020 | 6 January 2021 | 2 February 2021 | 2 February 2021 | Boca Chica, Texas | Destroyed | 1 |

| SN10 | September 2020 | 23 February 2021 | 3 March 2021 | 3 March 2021 | Boca Chica, Texas | Destroyed | 1 |

| SN11 | September 2020 | 22 March 2021 | 30 March 2021 | 30 March 2021 | Boca Chica, Texas | Destroyed | 1 |

| SN12 | September 2020 | N/A | N/A | February 2021 | Boca Chica, Texas | Scrapped | 0 |

| SN13 | October 2020 | N/A | N/A | February 2021 | Boca Chica, Texas | Scrapped | 0 |

| SN14 | October 2020 | N/A | N/A | February 2021 | Boca Chica, Texas | Scrapped | 0 |

| SN15 | November 2020 | 26 April 2021 | 5 May 2021 | 31 May 2021 | Boca Chica, Texas | Retired | 1 |

| SN16 | December 2020 | Not Yet | Not Yet | Unknown | Boca Chica, Texas | Retired | 0 |

| SN17 | December 2020 | N/A | N/A | May 2021 | Boca Chica, Texas | Scrapped | 0 |

| SN18 | January 2021 | N/A | N/A | June 2021 | Boca Chica, Texas | N/A | 0 |

| SN19 | February 2021 | N/A | N/A | June 2021 | Boca Chica, Texas | N/A | 0 |

| SN20/Ship 20 | March 2021 | 21 October 2021 | N/A | Not Yet | Boca Chica, Texas | Retired | 0 |

| Ship 21 | 3 July 2021 | Not Yet | Not Yet | Not Yet | Boca Chica, Texas | Scrapped | 0 |

| Ship 22 | September 2021 | Not Yet | Not Yet | Not Yet | Boca Chica, Texas | Suspended | 0 |

| Ship 23 | October 2021 | Not Yet | Not Yet | Not Yet | Boca Chica, Texas | Suspended | 0 |

| Ship 24 | November 2021 | Not Yet | Not Yet | Not Yet | Boca Chica, Texas | In service (ground testing) | 0 |

| Ship 25 | January 2022 | Not Yet | Not Yet | Not Yet | Boca Chica, Texas | Under Construction | 0 |

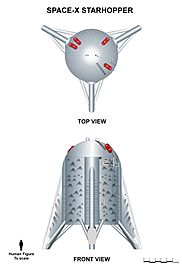

Starhopper

Construction on the initial test article—Starship Hopper, Hopper, or Starhopper began at Boca Chica in 2018 using 300-series stainless steel. The Starhopper had a single engine and was test flown to develop landing and low-altitude/low-velocity control algorithms.

In early 2019, a major focus was to complete the pressure vessel for the liquid methane and liquid oxygen tanks, including related plumbing. Starhopper's lower tank section was transported to the launch pad on 8 March. Integrated system testing—with the newly built ground support equipment (GSE) at the SpaceX South Texas facilities—began in March. Starhopper was fueled with LOX and liquid methane to test the pressurization systems, observed via icing fuel lines leading to the vehicle and the venting of cryogenic boil off at the launch/test site. For over a week, Starhopper underwent tanking tests, wet dress rehearsals, and pre-burner tests. A storm blew over and damaged Starhopper's nose cone. SpaceX then decided to test the Starhopper vehicle without one.

Flight tests

On 3 April 2019, SpaceX conducted a static fire test. The firing ran for a few seconds, and was marked successful. The vehicle might have lifted a few inches off the ground. In a second tethered test two days later the vehicle rose to about 1 metre altitude.

By May 2019, SpaceX was planning to add flight tests in Florida. SpaceX began building two high-altitude prototypes simultaneously, Mk1 in Texas and Mk2 in Florida, using competing teams. They were required to share progress, insights, and build techniques. These vehicles featured three Raptor methalox engines and were meant to reach an altitude 5 km (3.1 mi). An Mk3 prototype began construction in late-2019.

In September, externally-visible moving fins were added to Mk1. On 25 July, Starhopper made its initial flight test, a "hop" reaching approximately 20 m (66 ft) altitude. This was followed by a second hop on 27 August, rising approximately 150 m (490 ft) and landing approximately 100 m (330 ft) from the launchpad, the first use of the Raptor in flight.

Mark series (Mk1 - Mk4)

In September, Musk unveiled Starship Mk1. It was 9 m (30 ft) in diameter and approximately 50 m (160 ft) tall, with an empty mass of 200 t (440,000 lb). It was intended for testing flight and reentry profiles, pursuing a suborbital flight. It was briefly equipped with three sea-level Raptors, two fins each at the front and back, and a nose cone containing cold-gas reaction control thrusters. All of these were removed after the presentation.

Mk4 construction began in Florida in October. A few weeks later, work in Florida paused, with an 80% reduction in the workforce there, and Mk4 was scrapped. Some assemblies that had been built in Florida were transported to Texas.

On 20 November 2019, Mk1 blew apart during a pressure test. Mk2 was never completed. Work shifted to Mk3 and Mk4.

In December 2019, Musk redesignated Mk3 as Starship SN1 and predicted that minor design improvements would continue through SN20. In January 2020, SpaceX performed pressurization tests in Boca Chica. One test intentionally destroyed the tank by over-pressurizing it to 7.1 bar (710 kPa). Another tank underwent at least two pressurization tests; in the first experiment (27 January), the test tank withstood 7.5 bar (750 kPa) before springing a leak. The leak was repaired and the tank was then cryogenic pressure tested (29 January), when the tank ruptured under pressure of 8.5 bar (850 kPa). The test was considered a success as 8.5 bar achieved a safety factor of 1.4 (1.4 times the operational pressure).

SpaceX began construction of internal components for SN1 in December 2019 and began stacking it in February 2020 after successful pressurization tests on propellant tank prototypes. Although the weld quality of the rings had been improved, SN1 was destroyed during a cryogenic pressurization test (28 February) due to a design failure in the lower tank thrust structure. The structure ruptured from the bottom up, sending most of the top part flying.

Hops (SN3 - SN6)

Musk announced that SN3 was targeted at static fire tests and short hops, while SN4 would be used for longer flights.

SN3 was destroyed during testing on 3 April 2020 due to a bad testing configuration. The liquid oxygen tanks were pressurized with nitrogen in order to help them withstand the weight of the full methane tanks undergoing testing. A LOX valve was incorrectly opened, releasing pressure in one section. The section crumpled, causing the top section to fall off. SN4 was built reusing parts of SN3 not damaged during the mishap.

SN4 passed cryogenic pressure testing (26 April), the first prototype since the smaller SN2 test tank to do so. SN4 passed two static fires (5 and 7 May): one tested the main tanks, while the other tested the fuel header tank. After uninstalling the engine, a new cryogenic pressure test was conducted (19 May). Vibrations caused a leak in the methane fuel piping that ignited and spread to flammable insulation. The fire caused significant damage to the rocket's base and destroyed the control wiring. SN4 was destroyed after a static fire test of its single engine (29 May), due to a failure with the Ground Support Equipment's quick-disconnect function.

In March, Musk set a goal to conduct an orbital flight of Starship before the end of 2020. After a static fire test (30 July), SN5 completed a 150-meter flight (4 August) with engine SN27. SN6 completed a static fire (24 August) and completed a 150-meter hop test flight with engine SN29 (3 September).

In March 2021, SN5 was scrapped, followed by SN6 in January 2021.

Flights (SN8 - SN19)

SN8 was planned to be built out of 304L stainless steel, although some parts may have been made of 301 steel. In late October and November, SN8 survived four static fires. During the third test (12 November), debris from the pad caused the vehicle to lose pneumatics. The launch took place on 9 December. Launch, ascent, reorientation, and controlled descent were successful, but low pressure in the methane header tank, kept the engines from producing enough thrust for the landing burn, destroying SN8 via impact forces.

On 11 December, the stand beneath SN9 failed, causing the vehicle to tip and contact the walls inside the High Bay. SN9 then required a replacement forward flap. SN9 conducted 6 static fires in January 2021, including three separate static fires, spaced just hours apart. Engines 44 and 46 had to be replaced. After struggling to gain FAA permission to launch, SN9 conducted a 10 km (6.2 mi) flight test (2 February). Ascent, engine cutoffs, reorientation and controlled descent were stable, but one engine's oxygen pre-burner failed, sending SN9 crashing into the landing pad. The landing pad was then reinforced with an additional layer of concrete. After the SN9 failure, all three engines were used to perform the belly flop landing sequence. This offered a failsafe should one fail to ignite.

SN10's first cryogenic proof test succeeded (8 February), followed by a static fire (23 February). After an engine swap, another static fire came (25 February).

Two launch attempts were conducted on 3 March. The first attempt was automatically aborted after one engine produced too much thrust while throttling up. After a 3-hour delay to increase the tolerance, the second attempt landed without exploding, following the SN8/SN9 flight profile. The test ended with a hard landing-at 10 m/s-most likely due to partial helium ingestion from the fuel header tank. Three landing legs were not locked in place, producing a slight lean after landing. Although the vehicle initially remained intact, the impact crushed the legs and part of the leg skirt. Eight minutes later the prototype exploded, possibly from a methane leak.

SN11 accomplished a cryogenic proof test (12 March) that included testing of the Reaction Control System (RCS), followed by a static fire test (15 March). Immediately after ignition, the test was aborted. Another static fire attempt led to reports that one of the three engines had been removed for repairs. A replacement engine was installed and a third static fire was attempted (26 March ). A 10 km flight test was conducted in heavy fog (30 March). The test included engine cutoffs, flip maneuver, flap control and descent, along with a visible fire on engine 2 during the ascent. Just after the defective engine was re-ignited for the landing burn, SN11 lost telemetry at T+ 5:49 and disintegrated. A (relatively) small methane leak led to fire on engine 2 and fried part of the avionics, causing a hard start attempting landing burn in the CH4 turbopump. SN12 through SN14 never launched.

SN15 introduced improved avionics software, an updated aft skirt propellant architecture, and a new Raptor design and configuration. A Starlink antenna on the side of the vehicle was another new feature. SN15 underwent an ambient temperature pressure test (9 April), A cryogenic proof test (12 April), and a header tank cryogenic proof test (13 April). Then a static fire (26 April) and a header tank static fire (27 April) followed. A 10 km (33,000 ft) high-altitude flight test was conducted in heavy cloud on 5 May, achieving a soft touchdown. A small fire near the base was controlled shortly after landing. After its engines were removed, it was retired on 31 May, the first Starship prototype to fly, land and be recovered SN16,. SN17, SN18 and SN19 were scrapped/canceled.

Orbital launches (SN20/Ship 20-)

SN20 (Ship 20), was planned to be launched atop the Super Heavy booster. SN20's thermal protection system covers much of the vehicle.

SN20 rolled out to the launch mount on 5 August 2021 and was placed on Booster 4 for a fit test. The prototype was expected to fly atop booster BN4. FCC filings in May 2021 by SpaceX stated that the orbital flight would launch from Boca Chica. After separation, Starship would enter orbit and around 90 minutes later attempt a soft ocean landing around 100 km off the coast of Kauai.

Ship 21 was scrapped, Ship 22 moved out to the "Rocket Display Garden" in late February 2022, and is likely retired. Ship 23 was scrapped and partially recycled in Ship 24. Ship 24 is stacked, while parts have been spotted for Ship 25 (20 February) and Ship 26 (24 February).

Super Heavy prototypes

| Name | First spotted | First static fire | Maiden flight | Decommissioned | Construction site | Status | Flights |

|---|---|---|---|---|---|---|---|

| BN1 | September 2020 | N/A | N/A | 30 March 2021 | Boca Chica, Texas | Scrapped | 0 |

| BN3/B3 | March 2021 | 19 July 2021 | N/A | 14 August 2021 | Boca Chica, Texas | Scrapped | 0 |

| B4 | 3 July 2021 | Not Yet | Not Yet | 25 March 2022 | Boca Chica, Texas | Retired | 0 |

| B5 | 19 July 2021 | Not Yet | Not Yet | December 2021 | Boca Chica, Texas | Scrapped | 0 |

| B7 | 29 September 2021 | Not Yet | Not Yet | Not Yet | Boca Chica, Texas | Undergoing repairs | 0 |

| B8 | 25 January 2022 | Not Yet | Not Yet | Not Yet | Boca Chica, Texas | Under Construction | 0 |

Boosters do not have an engine skirt. Without engines, boosters are about 3 meters shorter.

BN1

BN1 was the first Super-Heavy Booster prototype, a pathfinder that was not intended for flight tests. Sections of the ~70 m (230 ft) tall test article were manufactured throughout the fall. Stacking began in December 2020. BN1 was fully stacked inside the High Bay on 18 March.

BN3/B3

BN3 (Booster 3) was used for ground tests. A cryogenic proof test was completed (13 July). Booster 3 completed stacking in the High Bay (29 June), and moved to the test pad without engines. Three engines were subsequently added to B3.

A static fire test was conducted 19 July. BN3/Booster 3 was partially scrapped on 15 August.

B4

Booster 4 first became visible on 3 July. Musk ordered several hundred SpaceX employees at Hawthorne to relocate to Boca Chica to accelerate the development of SN20, BN4, and the Orbital Launch Platform in an attempt to put the Starship system on the pad by 5 August. BN4 was fully stacked on 1 August, with a full complement of 29 engines installed on 2 August. Grid fins were added to support atmospheric reentry testing, but notably, the grid fins on the Booster 4 test article did not fold down for launch.

SN20 was stacked on top of Booster 4 on 6 August for a fitting test, making it the largest rocket ever. Booster 4 was then returned to the High Bay for secondary wiring. On 9 September, Booster 4 came again to the launch site on top of the Orbital Launch mount.

B4 completed its first cryogenic proof test (17 December), and a pneumatic proof test (19 December). It underwent another cryogenic proof test and a full-load cryogenic proof test. B4 and Ship 20 were then retired.

B5

Parts for B5 were observed as early as 19 July. Stacking for BN5 completed in November, although on 8 December, B5 retired to stand alongside SN15 and SN16.

B7

Parts for B7 were spotted on 29 September. B7 was placed on the orbital launch mount on 31 March 2022. After completing a cryogenic proof test on 4 April 2022, it was placed onto the new booster test stand on 8 April. B7 completed another cryogenic test on 14 April, but the downcomer suffered a failure and ruptured. On 18 April, B7 returned to the production site for repairs. On 5 May, B7 was again placed on the orbital launch mount. B7 then completed two cryogenic tests on 9 and 11 May. It then entered the new Mega Bay (also known as Wide Bay or High Bay 2), for more repairs and additional equipment, upgraded grid fins and engines, and two more 'chines' (triangular structures placed on the aft section to aid in aerodynamic control).

On 11 July, Booster 7 attempted a spin prime test, wherein its engines' turbopumps are spooled up without ignition. However, during the test, it experienced an anomaly and a small explosion. Initial reports from Elon Musk stated that minor damage occurred. It was later rolled back to the Mega Bay for inspection and repairs three days later.

B8

Parts for B8 were observed on 25 January.

Test tanks

The tanks are listed as follows:

| Name | First spotted | Decommissioned | Construction site | Cur. location | Status | Tests |

|---|---|---|---|---|---|---|

| TT1 | January 2020 | 10 January 2020 | Boca Chica, Texas | N/A | Intentionally destroyed | 1 |

| LOX HT | January 2020 | 25 January 2020 | Boca Chica, Texas | N/A | Intentionally destroyed | 2 |

| TT2 | January 2020 | 28 January 2020 | Boca Chica, Texas | N/A | Intentionally destroyed | 2 |

| SN2 | February 2020 | March 2020 | Boca Chica, Texas | Production site | Retired | 1 |

| SN7 | May 2020 | 23 June 2020 | Boca Chica, Texas | N/A | Intentionally destroyed | 2 |

| SN7.1 | July 2020 | 22 September 2020 | Boca Chica, Texas | N/A | Intentionally destroyed | 2 |

| SN7.2 | December 2020 | 22 May 2021 | Boca Chica, Texas | Production site | Retired | 2 |

| BN2.1 | 3 June 2021 | 25 June 2021 | Boca Chica, Texas | Production site | Retired | 2 |

| GSE 4.1 | August 2021 | 18 January 2021 | Boca Chica, Texas | Intentionally destroyed | 2 | |

| B2.1 | October 2021 | 6 December 2021 | Boca Chica, Texas | Production site | Retired | 3 |

| B6 | October 2021 | Not Yet | Boca Chica, Texas | Production site | Idle | 0 |

| B7.1 | 2022 | Not Yet | Boca Chica, Texas | Launch site | Testing | 4 |

| EDOME | 2022 | Not Yet | Boca Chica, Texas | Launch site | Idle | 0 |

TT1, LOX HTT, and TT2

Test Tank 1 (TT1) was a subscale test tank consisting of two forward bulkheads connected by a small barrel section. TT1 was used to test new materials and construction methods. On 10 January 2020, TT1 was tested to failure as part of an ambient temperature test reaching a pressure of 7.1 bar (710 kPa).

Liquid Oxygen Header Test Tank (LOX HTT) was similar to TT1, but was based on the LOX Header tank inside a nosecone section. On 24 January 2020, the tank underwent a pressurization test which lasted several hours. The following day it was tested to destruction.

Test Tank 2 (TT2) was another subscale test tank similar to TT1. On 27 January 2020, TT2 underwent an ambient temperature pressure test where it reached a pressure of 7.5 bar (750 kPa) before a leak occurred. Two days later, it underwent a cryogenic proof test to destruction, bursting at 8.5 bar.

Starship test tanks

SN2 was a half-size test tank used to test welding quality and thrust puck design. The thrust puck is found on the bottom of the vehicle where in later Starship tests up to three sea-level Raptor engines would be mounted. SN2 passed a pressure test on 8 March 2020.

SN7 was a pathfinder test article for the switch to type 304L stainless steel. A cryogenic proof test was performed in June 2020, achieving pressure of 7.6 bar (760 kPa) before a leak occurred. During a pressurize to failure test on 23 June 2020, the tank burst at an unknown pressure.

SN7.1 was the second 304L test tank, with the goal of reaching a higher failure pressure. The tank was repeatedly tested in September, and tested to destruction on 23 September. The tank burst at a pressure of 8 bar (800 kPa) near the top of the tank.

SN7.2 was created to test thinner walls, and therefore, lower mass. It is believed to be constructed from 3 mm steel sheets rather than the 4 mm thickness of its predecessors. On 26 January 2021, SN7.2 passed a cryogenic proof test. On 4 February, during a pressurize to failure test, the tank developed a leak, which was repaired. On 15 March, SN7.2 was retired.

Super Heavy test tanks

BN2.1 was rolled out on 3 June 2021 for cryogenic tests (8 June) and (17 June).

B2.1 (not BN2.1) made cryogenic tests (1 and 2, and 3 December) and then retired.

Parts for B6 were observed on 22 August 2021. On 8 December 2021, B6 was slated to become a test tank.

B7.1 was first cryogenically proof tested on 28 June 2022, and tested again on 19 July 2022. During a pressurize to failure test two days later, it received minor damage. After repairs, it underwent a fourth cryogenic proof test on 27 July 2022.

GSE test tanks

GSE 4.1 was first spotted in August 2021, and was the first GSE test tank built, made from parts of GSE 4. It underwent a cryogenic proof test (23 August). It underwent a cryogenic proof test to failure on 8 January 2022.

Other test tanks

EDOME is a simplified test tank, which has not been tested yet.