Sucrose facts for kids

| Sucrose | |

|---|---|

| General | |

| Systematic name | Sucrose |

| Other names | Sugar, Saccharose |

| atomic formula | C12H22O11 |

| SMILES | OC1C(OC(CO)C(O)C1O) OC2(CO)OC(CO)C(O)C2O |

| Molar mass | 342.29648 g/mol |

| Appearance | white solid |

| CAS number | [57-50-01] |

| Chemical Properties | |

| Density and phase | 1.587 g/cm³, solid |

| Solubility in water | 211.5 g/100 ml (25°C) |

| Melting point | 186°C (459.15 K) |

| Boiling point | decomposition |

| Chiral rotation [α]D | +66.47° |

| Refractive index | 1.5376 |

| Structure | |

| Molecular shape | ? |

| Crystal structure | monoclinic hemihedral |

| Dipole moment | ? D |

| Hazards | |

| MSDS | External MSDS |

| Main hazards | Combustible |

| NFPA 704 | |

| Flash point | N/A |

| R/S statement | R: ? S: ? |

| RTECS number | WN6500000 |

| Supplementary data page | |

| Structure and properties |

n, εr, etc. |

| Thermodynamic data |

Phase behaviour Solid, liquid, gas |

| Spectral data | UV, IR, NMR, MS |

| Related compounds | |

| Other anions | ? |

| Other cations | ? |

| Except where noted otherwise, data are given for materials in their standard state (at 25°C, 100 kPa) Infobox disclaimer and references |

|

| Solubility of Pure Sucrose | |

|---|---|

| Temperature(C) | g sucrose/g water |

| 50 | 2.59 |

| 55 | 2.73 |

| 60 | 2.89 |

| 65 | 3.06 |

| 70 | 3.25 |

| 75 | 3.46 |

| 80 | 3.69 |

| 85 | 3.94 |

| 90 | 4.20 |

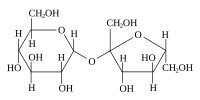

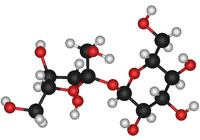

Sucrose (common name: table sugar, also called saccharose) is a disaccharide (glucose + fructose) with the molecular formula C12H22O11. Its systematic name is α-D-glucopyranosyl-(1→2)-β-D-fructofuranose. It is best known for its role in human nutrition and is formed by plants but not by higher organisms.

Contents

Physical and chemical properties

Pure sucrose is most often prepared as a fine, white, odorless crystalline powder with a pleasing, sweet taste.

Production

History of sucrose refinement

The production of table sugar has a long history. Some scholars claim Indians discovered how to crystallize sugar during the Gupta dynasty, around AD 350.

Other scholars point to the ancient manuscripts of China, dated to the 8th century BC, where one of the earliest historical mentions of sugar cane is included along with the fact that their knowledge of sugar cane was derived from India. Further, it appears that by about 500 BC, residents of present-day India began making sugar syrup and cooling it in large flat bowls to make raw table sugar crystals that were easier to store and transport. In the local Indian language, these crystals were called khanda (खण्ड), which is the source of the word candy.

The army of Alexander the Great was halted on the banks of river Indus by the refusal of his troops to go further east. They saw people in the Indian subcontinent growing sugarcane and making granulated, salt-like sweet powder, locally called sākhar (साखर), pronounced as sakcharon (ζακχαρον) in Greek (Modern Greek, zachari ζάχαρη). On their return journey, the Greek soldiers carried back some of the "honey-bearing reeds". Sugarcane remained a limited crop for over a millennium. Sugar was a rare commodity and traders of sugar became wealthy. Venice, at the height of its financial power, was the chief sugar-distributing center of Europe. Arabs started producing it in Sicily and Spain. Only after the Crusades did it begin to rival honey as a sweetener in Europe. The Spanish began cultivating sugarcane in the West Indies in 1506 (Cuba in 1523). The Portuguese first cultivated sugarcane in Brazil in 1532.

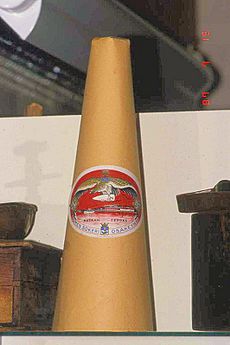

Sugar remained a luxury in much of the world until the 18th century. Only the wealthy could afford it. In the 18th century, the demand for table sugar boomed in Europe and by the 19th century it had become regarded as a human necessity. The use of sugar grew from use in tea, to cakes, confectionery and chocolates. Suppliers marketed sugar in novel forms, such as solid cones, which required consumers to use a sugar nip, a pliers-like tool, in order to break off pieces.

The demand for cheaper table sugar drove, in part, colonization of tropical islands and nations where labor-intensive sugarcane plantations and table sugar manufacturing could thrive. Growing sugar cane crop in hot humid climates, and producing table sugar in high temperature sugar mills was harsh, inhumane work. The demand for cheap and docile labor for this work, in part, first drove slave trade from Africa (in particular West Africa), followed by indentured labor trade from South Asia (in particular India). Millions of slaves, followed by millions of indentured laborers were brought into the Caribbean, Indian Ocean, Pacific Islands, East Africa, Natal, north and eastern parts of South America, and southeast Asia. The modern ethnic mix of many nations, settled in the last two centuries, has been influenced by table sugar.

Beginning in the late 18th century, the production of sugar became increasingly mechanized. The steam engine first powered a sugar mill in Jamaica in 1768, and, soon after, steam replaced direct firing as the source of process heat. During the same century, Europeans began experimenting with sugar production from other crops. Andreas Marggraf identified sucrose in beet root and his student Franz Achard built a sugar beet processing factory in Silesia (Prussia). The beet-sugar industry took off during the Napoleonic Wars, when France and the continent were cut off from Caribbean sugar. In 2010, about 20 percent of the world's sugar was produced from beets.

Today, a large beet refinery producing around 1,500 tonnes of sugar a day needs a permanent workforce of about 150 for 24-hour production.

Trends

Table sugar (sucrose) comes from plant sources. Two important sugar crops predominate: sugarcane (Saccharum spp.) and sugar beets (Beta vulgaris), in which sugar can account for 12% to 20% of the plant's dry weight. Minor commercial sugar crops include the date palm (Phoenix dactylifera), sorghum (Sorghum vulgare), and the sugar maple (Acer saccharum). Sucrose is obtained by extraction of these crops with hot water; concentration of the extract gives syrups, from which solid sucrose can be crystallized. In 2017, worldwide production of table sugar amounted to 185 million tonnes.

Most cane sugar comes from countries with warm climates, because sugarcane does not tolerate frost. Sugar beets, on the other hand, grow only in cooler temperate regions and do not tolerate extreme heat. About 80 percent of sucrose is derived from sugarcane, the rest almost all from sugar beets.

In mid-2018, India and Brazil had about the same production of sugar – 34 million tonnes – followed by the European Union, Thailand, and China as the major producers. India, the European Union, and China were the leading domestic consumers of sugar in 2018.

Beet sugar comes from regions with cooler climates: northwest and eastern Europe, northern Japan, plus some areas in the United States (including California). In the northern hemisphere, the beet-growing season ends with the start of harvesting around September. Harvesting and processing continues until March in some cases. The availability of processing plant capacity and the weather both influence the duration of harvesting and processing – the industry can store harvested beets until processed, but a frost-damaged beet becomes effectively unprocessable.

The United States sets high sugar prices to support its producers, with the effect that many former purchasers of sugar have switched to corn syrup (beverage manufacturers) or moved out of the country (candy manufacturers).

The low prices of glucose syrups produced from wheat and corn (maize) threaten the traditional sugar market. Used in combination with artificial sweeteners, they can allow drink manufacturers to produce very low-cost goods.

High-fructose corn syrup

High-fructose corn syrup (HFCS) is significantly cheaper as a sweetener for food and beverage manufacturing than refined sucrose. This has led to sucrose being partially displaced in U.S. industrial food production by HFCS and other non-sucrose natural sweeteners.

Although reports in public media regard HFCS as unhealthy, clinical dietitians, medical professionals, and the United States Food and Drug Administration (FDA) dismiss such concerns because "Sucrose, HFCS, invert sugar, honey, and many fruits and juices deliver the same sugars in the same ratios to the same tissues within the same time frame to the same metabolic pathways". While scientific authorities agree that dietary sugars are a source of empty calories associated with certain health problems, the belief that glucose-fructose syrups such as HFCS are especially unhealthy is not supported by scientific evidence. Health authorities and the FDA recommend limiting the overall consumption of sugar-based sweeteners.

Types

Cane

Since the 6th century BC, cane sugar producers have crushed the harvested vegetable material from sugarcane in order to collect and filter the juice. They then treat the liquid (often with lime (calcium oxide)) to remove impurities and then neutralize it. Boiling the juice then allows the sediment to settle to the bottom for dredging out, while the scum rises to the surface for skimming off. In cooling, the liquid crystallizes, usually in the process of stirring, to produce sugar crystals. Centrifuges usually remove the uncrystallized syrup. The producers can then either sell the sugar product for use as is, or process it further to produce lighter grades. The later processing may take place in another factory in another country.

Sugarcane is a major component of Brazilian agriculture; the country is the world's largest producer of sugarcane and its derivative products, such as crystallized sugar and ethanol (ethanol fuel).

Beet

Beet sugar producers slice the washed beets, then extract the sugar with hot water in a "diffuser". An alkaline solution ("milk of lime" and carbon dioxide from the lime kiln) then serves to precipitate impurities (see carbonatation). After filtration, evaporation concentrates the juice to a content of about 70% solids, and controlled crystallisation extracts the sugar. A centrifuge removes the sugar crystals from the liquid, which gets recycled in the crystalliser stages. When economic constraints prevent the removal of more sugar, the manufacturer discards the remaining liquid, now known as molasses, or sells it on to producers of animal feed.

Sieving the resultant white sugar produces different grades for selling.

Cane versus beet

It is difficult to distinguish between fully refined sugar produced from beet and cane. One way is by isotope analysis of carbon. Cane uses C4 carbon fixation, and beet uses C3 carbon fixation, resulting in a different ratio of 13C and 12C isotopes in the sucrose. Tests are used to detect fraudulent abuse of European Union subsidies or to aid in the detection of adulterated fruit juice.

Sugar cane tolerates hot climates better, but the production of sugar cane needs approximately four times as much water as the production of sugar beet. As a result, some countries that traditionally produced cane sugar (such as Egypt) have built new beet sugar factories since about 2008. Some sugar factories process both sugar cane and sugar beets and extend their processing period in that way.

The production of sugar leaves residues that differ substantially depending on the raw materials used and on the place of production. While cane molasses is often used in food preparation, humans find molasses from sugar beets unpalatable, and it consequently ends up mostly as industrial fermentation feedstock (for example in alcohol distilleries), or as animal feed. Once dried, either type of molasses can serve as fuel for burning.

Pure beet sugar is difficult to find, so labelled, in the marketplace. Although some makers label their product clearly as "pure cane sugar", beet sugar is almost always labeled simply as sugar or pure sugar. Interviews with the 5 major beet sugar-producing companies revealed that many store brands or "private label" sugar products are pure beet sugar. The lot code can be used to identify the company and the plant from which the sugar came, enabling beet sugar to be identified if the codes are known.

Culinary sugars

Mill white

Mill white, also called plantation white, crystal sugar or superior sugar is produced from raw sugar. It is exposed to sulfur dioxide during the production to reduce the concentration of color compounds and helps prevent further color development during the crystallization process. Although common to sugarcane-growing areas, this product does not store or ship well. After a few weeks, its impurities tend to promote discoloration and clumping; therefore this type of sugar is generally limited to local consumption.

Blanco directo

Blanco directo, a white sugar common in India and other south Asian countries, is produced by precipitating many impurities out of cane juice using phosphoric acid and calcium hydroxide, similar to the carbonatation technique used in beet sugar refining. Blanco directo is more pure than mill white sugar, but less pure than white refined.

White refined

White refined is the most common form of sugar in North America and Europe. Refined sugar is made by dissolving and purifying raw sugar using phosphoric acid similar to the method used for blanco directo, a carbonatation process involving calcium hydroxide and carbon dioxide, or by various filtration strategies. It is then further purified by filtration through a bed of activated carbon or bone char. Beet sugar refineries produce refined white sugar directly without an intermediate raw stage.

White refined sugar is typically sold as granulated sugar, which has been dried to prevent clumping and comes in various crystal sizes for home and industrial use:

- Coarse-grain, such as sanding sugar (also called "pearl sugar", "decorating sugar", nibbed sugar or sugar nibs) is a coarse grain sugar used to add sparkle and flavor atop baked goods and candies. Its large reflective crystals will not dissolve when subjected to heat.

- Granulated, familiar as table sugar, with a grain size about 0.5 mm across. "Sugar cubes" are lumps for convenient consumption produced by mixing granulated sugar with sugar syrup.

- Caster (0.35 mm), a very fine sugar in Britain and other Commonwealth countries, so-named because the grains are small enough to fit through a sugar caster which is a small vessel with a perforated top, from which to sprinkle sugar at table. Commonly used in baking and mixed drinks, it is sold as "superfine" sugar in the United States. Because of its fineness, it dissolves faster than regular white sugar and is especially useful in meringues and cold liquids. Caster sugar can be prepared at home by grinding granulated sugar for a couple of minutes in a mortar or food processor.

- Powdered, 10X sugar, confectioner's sugar (0.060 mm), or icing sugar (0.024 mm), produced by grinding sugar to a fine powder. The manufacturer may add a small amount of anticaking agent to prevent clumping — either cornstarch (1% to 3%) or tri-calcium phosphate.

Brown sugar comes either from the late stages of cane sugar refining, when sugar forms fine crystals with significant molasses content, or from coating white refined sugar with a cane molasses syrup (blackstrap molasses). Brown sugar's color and taste becomes stronger with increasing molasses content, as do its moisture-retaining properties. Brown sugars also tend to harden if exposed to the atmosphere, although proper handling can reverse this.

See also

In Spanish: Sacarosa para niños

In Spanish: Sacarosa para niños